Automation is no longer a futuristic concept; it has become a defining force in modern manufacturing, reshaping how products are made, how companies operate, and how investors evaluate opportunities. As advanced technologies permeate factory floors, manufacturing stocks are experiencing a profound transformation driven by efficiency gains, cost savings, and innovation acceleration.

The global industrial automation landscape is witnessing robust expansion, with the market projected to reach $226.8 billion in 2025, up from $206 billion in 2024. This growth is underpinned by a remarkable 10.8% CAGR through 2030, signaling long-term momentum for both hardware and software solutions.

Despite a temporary slowdown in 2024–2025 due to supply chain recalibrations and cautious investment climates, analysts anticipate a V-shaped recovery forecast through 2030. Companies that maintain strategic automation investments now are poised to emerge as leaders when growth accelerates.

At the heart of this transformation is the integration of artificial intelligence and robotics. Manufacturers are employing multimodal AI systems for design, prototyping, and R&D, enabling teams to reduce time-to-market by 50% and lower costs by 30%. These efficiencies are particularly pronounced in sectors such as automotive and aerospace, where rapid iteration and high precision are critical.

Generative AI tools can now simulate entire production workflows before physical assembly begins, identifying bottlenecks and optimizing processes. Meanwhile, robotic process automation (RPA) is delivering an astonishing 30% to 200% ROI in the first year for back-office and logistical functions.

The COVID-19 pandemic exposed vulnerabilities in global supply chains, prompting a wave of reshoring initiatives. Manufacturers are relocating facilities closer to end markets, bolstering resilience and reducing lead times. This shift is redirecting investor focus toward North American stocks, as domestic plants equipped with advanced automation can adapt more rapidly to demand fluctuations.

Small and medium-sized manufacturers (SMMs) are also gaining access to automation technologies that were once exclusive to large enterprises. Cloud-based control systems, modular robotics, and subscription-based software are democratizing innovation, allowing SMMs to compete on efficiency and quality.

Far from eliminating jobs wholesale, automation is expected to reshape the labor market. While up to 92 million roles may be displaced by 2030, roughly 170 million new positions are projected to emerge, resulting in a net gain of 78 million jobs globally. Over 90% of workers surveyed report that automation increases their productivity, enabling upskilling and redeployment into higher-value tasks.

However, the transition is not without challenges. Approximately 70% of digital transformation and automation projects fail to meet their objectives, often due to cultural resistance or a lack of integrated planning. Successful implementation requires aligning technology, processes, and people in a cohesive strategy.

Automation adoption and impact vary by industry and geography. Key sectors leading the charge include:

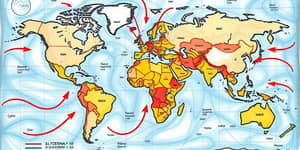

Regionally, Asia-Pacific commands 39% of global automation revenue, driven by government incentives and manufacturing hubs in China, Japan, and South Korea. North America excels in process automation, particularly in food & beverage, chemicals, and finance-linked manufacturing operations.

For investors, automation translates into stronger margins, predictable cost structures, and enhanced operational resilience. Companies that lead in automation adoption often enjoy:

Nevertheless, short-term volatility can arise from inventory corrections, supply chain disruptions, or macroeconomic shifts. Savvy investors assess balance sheets, R&D pipelines, and integration roadmaps to differentiate firms with robust automation strategies from those merely investing in technology without operational alignment.

To capitalize on automation’s potential, stakeholders should consider:

By prioritizing these criteria, investors can identify manufacturing stocks with sustainable competitive advantages and resilient growth trajectories.

Automation is fundamentally reshaping manufacturing, driving efficiency and innovation while transforming labor markets and supply chains. For investors, the most compelling opportunities lie with firms that integrate technology seamlessly into operations, manage workforce impacts proactively, and adapt to regional dynamics.

As the market recovers from short-term headwinds, automation leaders will likely outperform peers, benefiting from enhanced margins, accelerated R&D cycles, and robust resilience against disruptions. In this era of digital transformation, understanding and leveraging automation will be key to long-term investment success.

References